In today's rapidly developing technological era, PCB (Printed Circuit Board) has become an indispensable component in electronic products, and SMT (Surface Mount Technology) is one of the core processes of modern electronic manufacturing. The wide application and continuous innovation of SMT PCB Assembly provide strong support for the miniaturization, lightweight and high performance of electronic products.

SMT PCB Assembly, surface mount printed circuit board assembly technology, is a manufacturing process for mounting electronic components such as resistors, capacitors, IC chips, etc. on PCB boards. Compared with traditional plug-in assembly technology, SMT has the advantages of higher assembly density, smaller volume and weight, and lower cost. Therefore, it has been widely used in consumer electronics, communication equipment, automotive electronics and other fields.

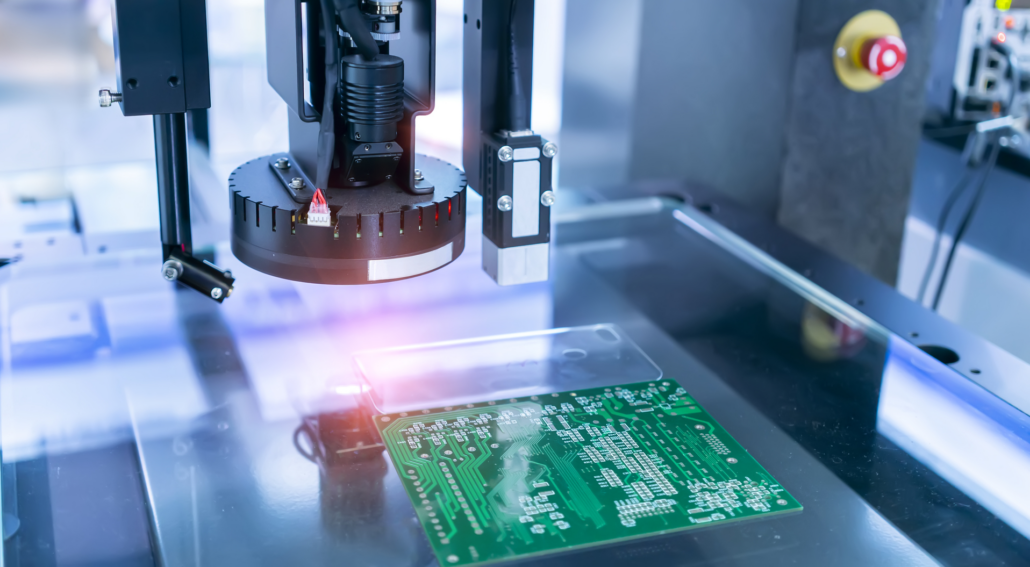

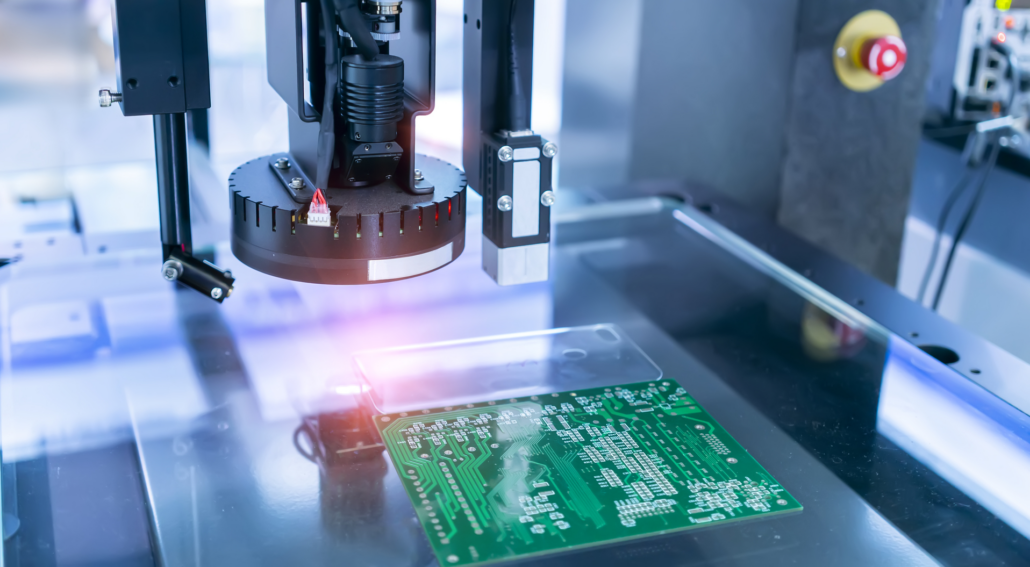

With the continuous development of technology, SMT PCB Assembly technology is also constantly innovating and progressing. The new generation of SMT technology uses advanced equipment such as high-precision placement machines, high-precision welding equipment, and automated testing equipment to achieve high-precision, high-efficiency, and high-reliability production. At the same time, new electronic components and materials are also emerging, providing more choices and possibilities for SMT PCB Assembly.

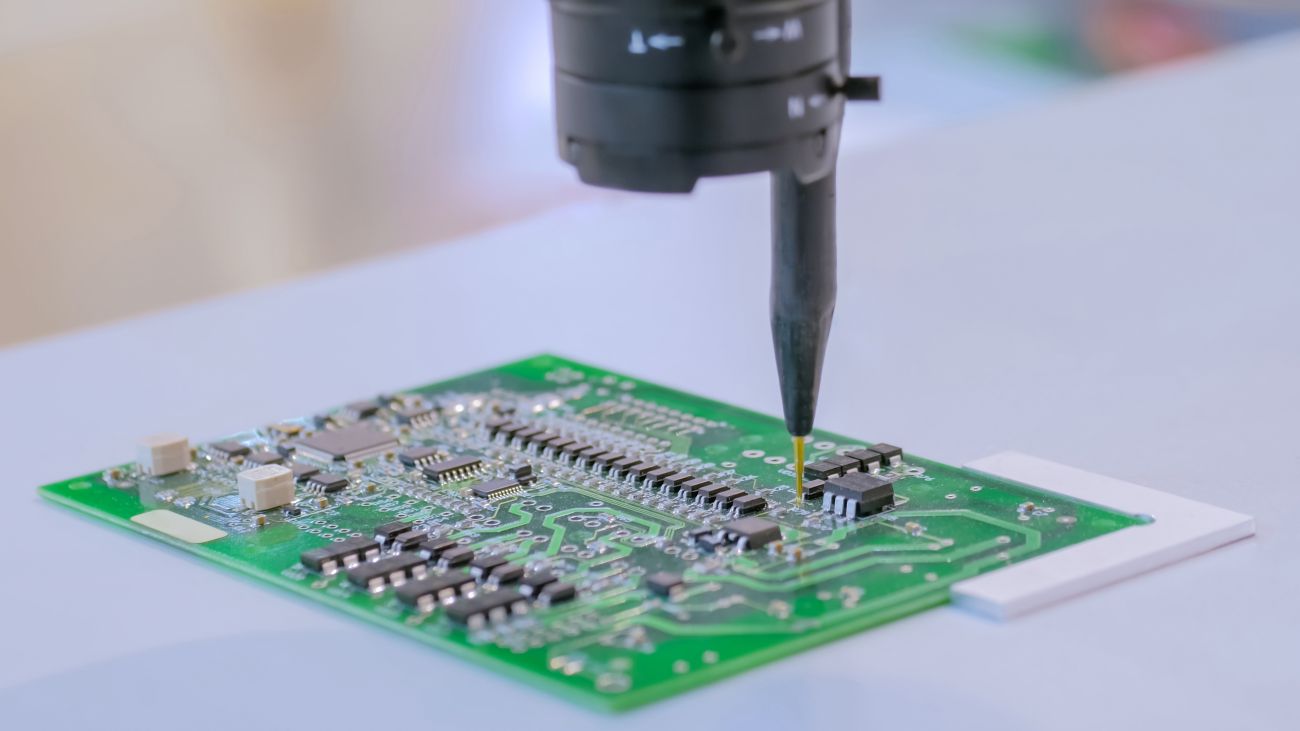

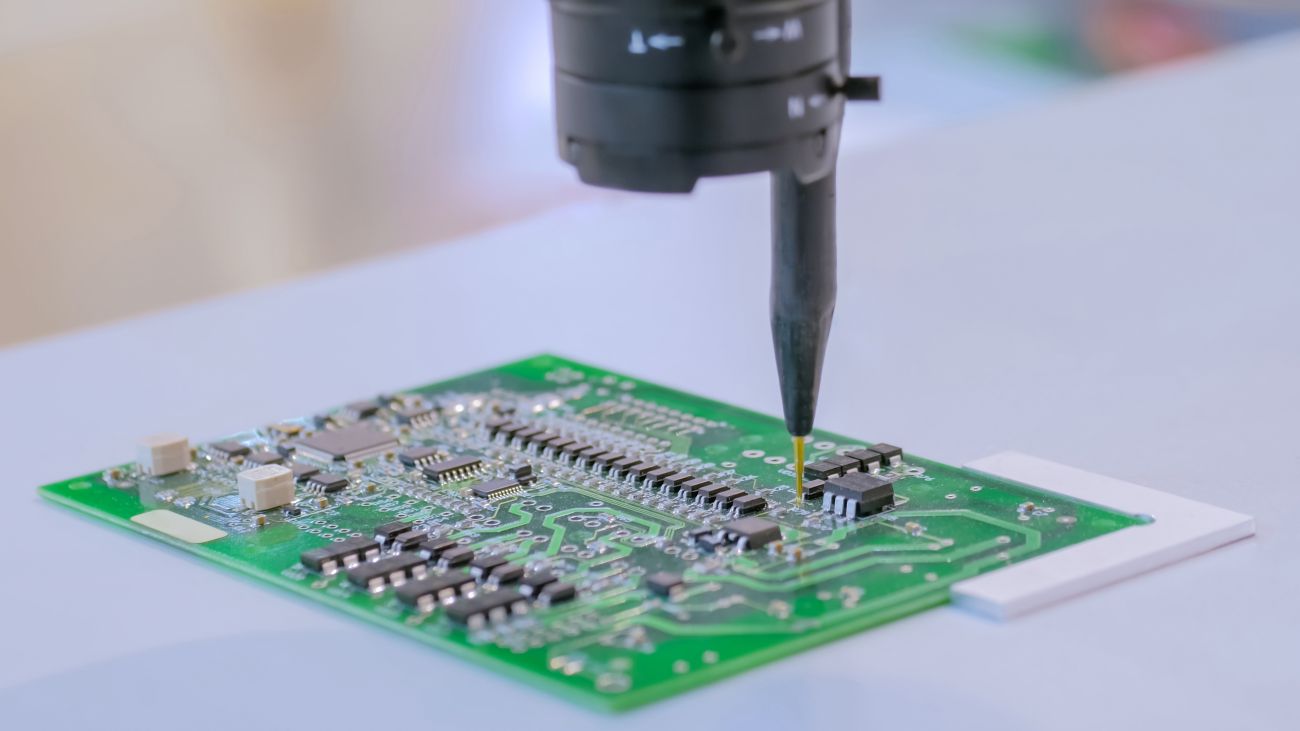

In the production process of SMT PCB Assembly welding quality is crucial. The quality of welding directly affects the performance and life of electronic products. Therefore, modern SMT production lines are equipped with automatic welding equipment and welding quality testing equipment to ensure the stability and reliability of welding quality.

In addition to welding quality, the assembly accuracy of SMT PCB Assembly is also an important factor affecting product quality. High-precision placement machines and welding equipment can effectively improve assembly accuracy and reduce component dislocation and shedding. At the same time, automated assembly equipment and testing equipment can also improve production efficiency and product quality.

With the development of emerging technologies such as 5G, Internet of Things, and artificial intelligence, the needs and application scenarios of PCB and SMT PCB Assembly will become more extensive. In the future, SMT PCB Assembly technology will continue to develop in the direction of high precision, high efficiency, and high reliability, providing strong support for the upgrading and innovation of the electronic manufacturing industry.

In addition, with the increasing awareness of environmental protection, green manufacturing and sustainable development have become important issues in the electronics manufacturing industry. In the field of SMT PCB Assembly, the application of environmentally friendly technologies such as lead-free soldering and environmentally friendly cleaning has become an industry trend. The application of these technologies is not only beneficial to environmental protection, but can also improve product quality and reliability and reduce production costs.

In terms of lead-free soldering, it has become an industry consensus to use lead-free solder instead of traditional lead-containing solder. Lead-free solder has better physical and chemical properties, which can improve soldering quality and product reliability. At the same time, the environmental protection of lead-free solder also meets the requirements of green manufacturing.

In terms of environmentally friendly cleaning, traditional cleaning methods often use large amounts of chemical solvents, which not only pollutes the environment but also endangers the health of workers. Therefore, new environmentally friendly cleaning technologies such as water-based cleaning and semi-aqueous cleaning are gradually being widely used. These cleaning technologies use environmentally friendly solvents, are environmentally friendly, have good cleaning effects, and can meet the high requirements of modern electronic manufacturing.

To sum up, SMT PCB Assembly is one of the core processes of modern electronic manufacturing, and its development status directly affects the development trend of the electronics industry. With the continuous advancement of technology and the continuous expansion of application scenarios, SMT PCB Assembly will continue to play an important role in promoting innovation and development in the electronic manufacturing industry. At the same time, green manufacturing and sustainable development will also play an increasingly important role in SMT PCB Assembly, promoting the environmental protection and sustainable development of the electronic manufacturing industry.

English

English