Why White Residue Still Appear on PCB After Cleaning

Today a client sent us some photos of the assembled PCB that ordered from other factory.

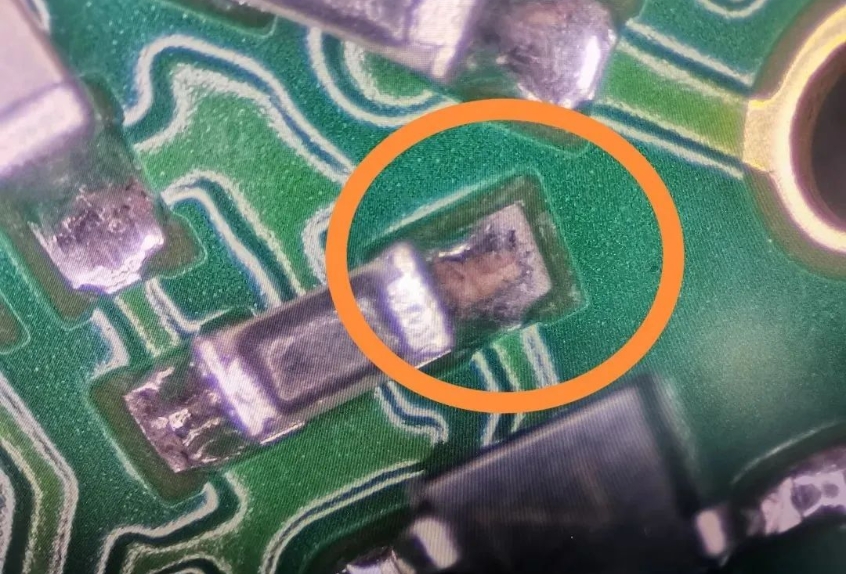

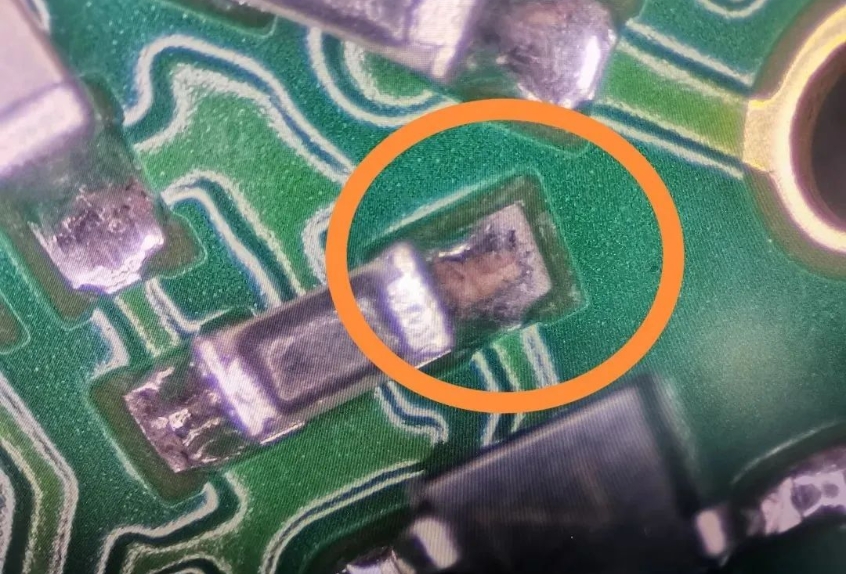

From these photos we could clearly notice that, some white residue are attached to the PCB ( mainly concentrated around the solder Pins and pads of the components )

This problem make the PCB appearance not looks clean, will affect selling and increase the probability of board failure.

Why this kind of white residue appear?

The root cause is that the first cleaning after soldering is not clean.

Some flux residue on the surface of the board, flux contains rosin resin compounds, in the absorption of moisture in the air, water molecules and resin in the combination of hydrophilic groups, the formation of a hydrate ( rosin resin hydrate ).

This rosin resin hydrate is not visible to the naked eye under dry environmental conditions. However, it changes the solvent solubility characteristics of rosin resin, making it difficult to be cleaned off by solvent solubility.

When the humidity of the environment increases, the rosin resin hydrate will turn white because it absorbs the water molecules in the air;

However, if we bake the assembled PCB at this time, most of the water molecules will evaporate, and the board surface will return to its normal appearance.

Two Tips to aviod this kind of PCB white residue problem

A : Clean the PCB within 4 to 6 hours after soldering

Rosin based fluxes will increase the probability of this white residue problems on PCB.

If the solder paste or flux is rosin based, then we recommend the cleaning within 4 to 6 hours after soldering.

If cleaning is done after 8 hours of soldering, there is a high probability of white residue problems.

B : Do not re-use the cleaner or cleaning tool too many times.

The cleaner and cleaning tools will attached with too much rosin resin hydrate after recycling too many times.

C: Use heated water-based cleaner if white residue appear on PCB

Try soaking the defective PCB in a heated water-based cleaner, and scrubbing it with an anti-static brush, it might take care of this kind of white residue.

English

English