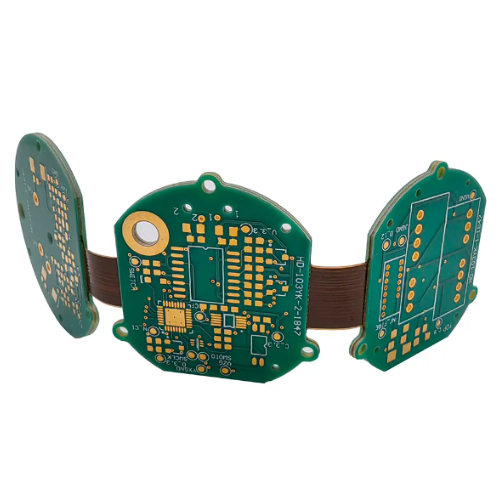

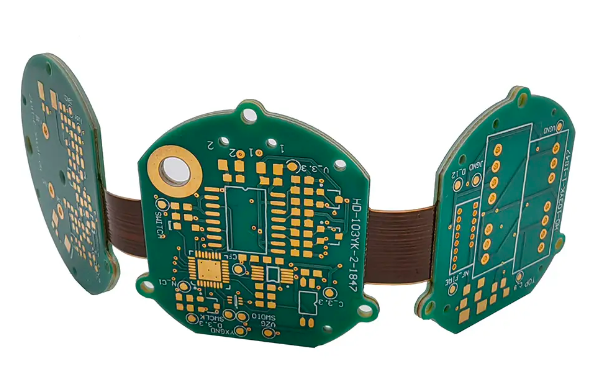

Rigid-Flex PCB

Rigid-Flex PCB Manufacturing

Smart Chiplink RIGID-FLEX PCB CAPABILITIES

|

Thickness of Finished Product ( Flex Part, No Stiffener ):

|

0.05-0.5mm ( Ultimate:0.5-0.8mm )

|

|

Thickness of Finished Product ( Rigid Part ):

|

0.2-6.0mm

|

|

Finished Copper Thickness:

|

0.5-5 OZ

|

|

Min Tracing/Spacing:

|

3mil / 3mil

|

|

Surface Finish:

|

HASL/OSP - RoHS

ENIG / Hard Gold / Immersion Silver

|

|

Impedance Control:

|

310%

|

|

Min Laser Hole:

|

0.1mm

|

|

Min Drilling Hole Diameter:

|

8mil

|

|

Other Techniques:

|

HDI

Gold Fingers

Stiffener ( Only for PI / FR4 Substrate )

|

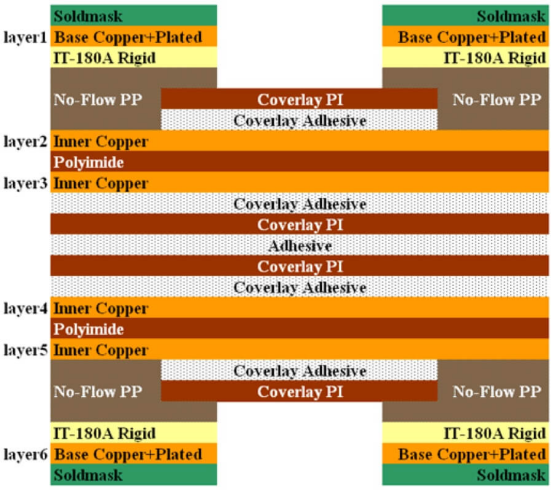

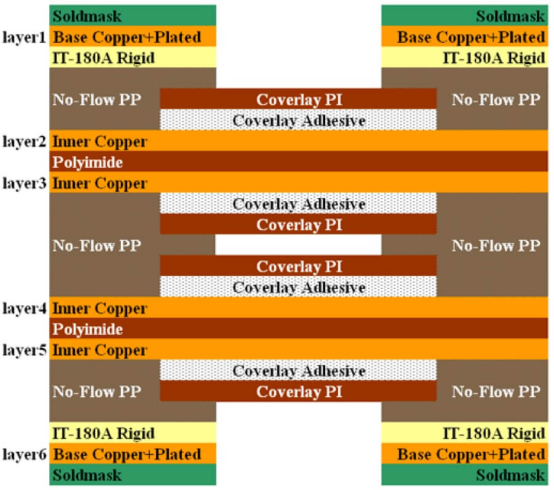

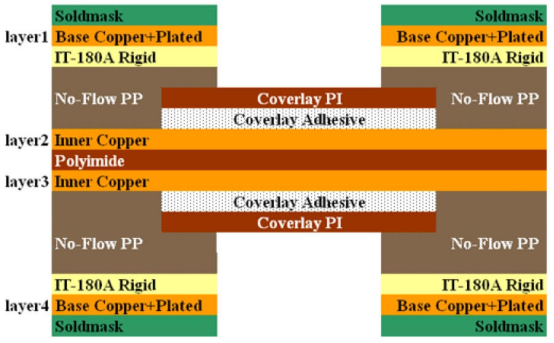

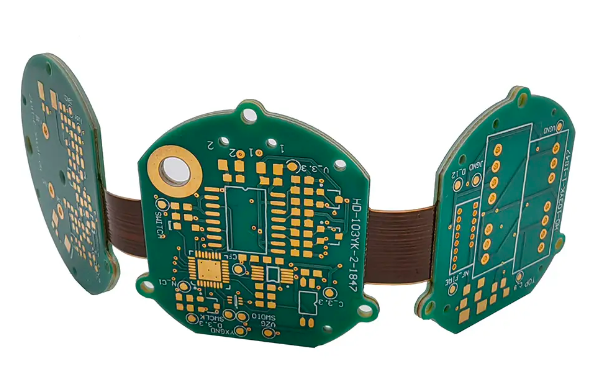

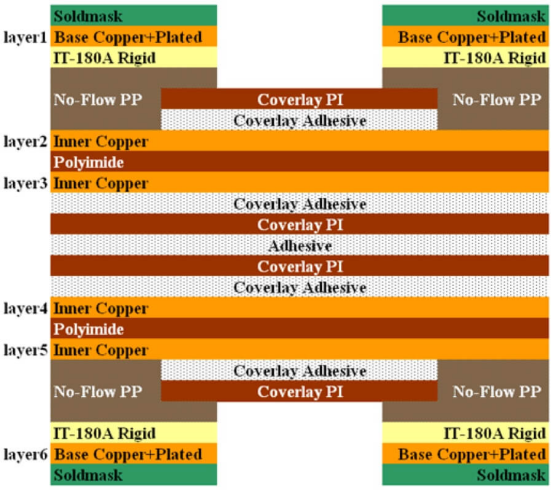

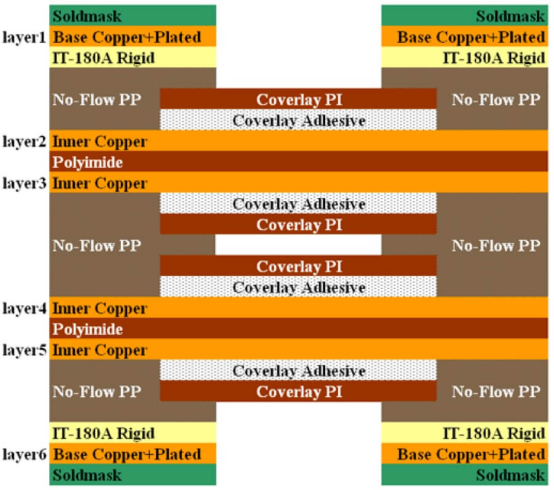

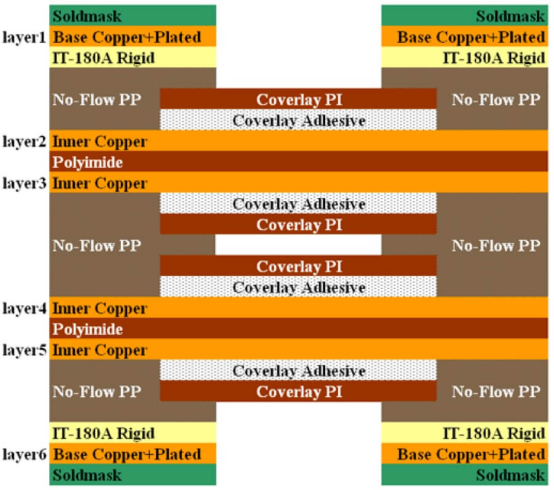

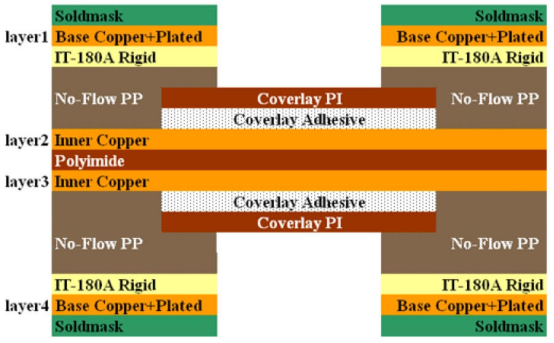

RIGID-FLEX PCB STACK-UP STRUCTURES AND DESIGN

Non-lamination flex&rigid board :

Lamination flex&rigid board :

Flex layer in Inner layer :

Flex layer on outlayer :

MATERIALS OF RIGID-FLEX PCBS

|

Conductors

|

·Rolled annealed ( RA ) copper

·Electro deposited ( ED ) copper

|

|

Adhesives

|

. Epoxy

·Acrylic

·Pre-preg

·Pressure Sensitive Adhesive ( PSA )

·Adhesiveless base material

|

|

Insulators

|

·FR-4

·Polyimide

·Polyester, Polyethylene Naphthalate ( PEN ), and Polyethylene

·Terephthalate ( PET )

·Solder mask/Flexible solder mask

·Photo image-able cover lay ( PIC )

|

|

Finishes

|

·Solder ( Tin / Lead or RoHS compliant ) Tin

·Immersion Nickel / Gold / Silver

·Hard Nickel / gold

·OSP

|

rigid flex pcb manufacturing process

English

English